Advanced Injection Molding Techniques and Their Industrial Applications #

Multiplas offers a diverse range of technical injection molding solutions tailored to meet the evolving needs of modern manufacturing. Below is an in-depth look at the primary injection molding applications, their processes, and typical areas of use.

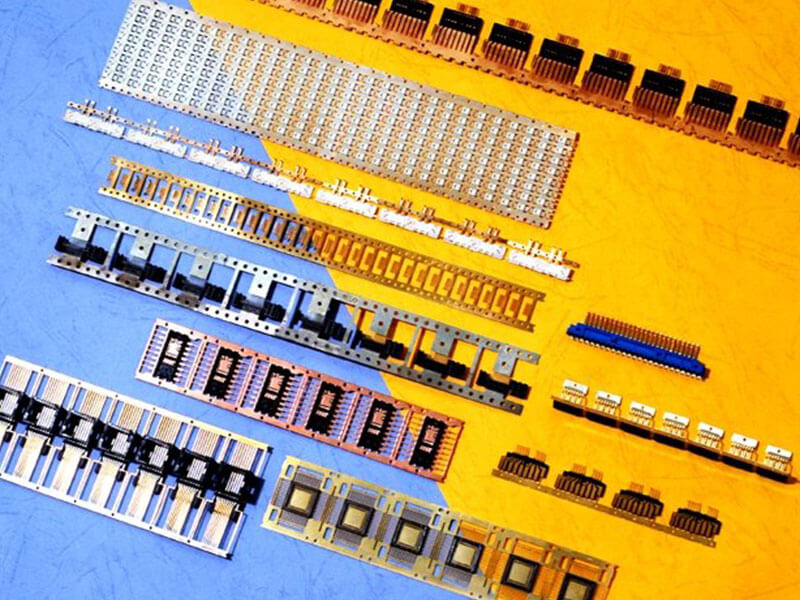

Insert Molding #

Insert molding is an efficient process that integrates metal stampings, bushings, electro-mechanical components, filtration materials, and other discrete parts into a single component. This is achieved by injecting thermoplastic around precisely positioned inserts or parts, resulting in a unified product with enhanced functionality and durability.

Related Products: GENERAL PURPOSE FOR SINGLE-COMPONENT

Multi-component (or Multi-color) Molding #

Multi-component molding combines two or more different materials into a single plastic part, enabling specific functions such as hard/soft combinations (e.g., PP and TPE), core/skin structures, and multi-color designs. The mold may rotate, shuttle, or swivel to position the cavity for each component, allowing for complex and functional product designs.

Related Products: GENERAL PURPOSE FOR MULTI-COMPONENT OR MULTI-COLOR

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

multi-component-molding

Thermoset Injection Molding #

The thermoset injection molding process starts with granular or pelletized material fed into a hopper, then gravity-fed into a heated barrel and screw. The material is injected into a heated mold under high pressure, filling all cavities. Once cured, the mold opens for part removal, which can be done manually or automatically. This method is ideal for producing durable, heat-resistant components.

Related Products: THERMOSET (BMC, RUBBER ETC.)

Liquid Injection Moulding #

Liquid silicone rubber (LSR) injection molding is designed for high-volume production of flexible, durable parts. LSR is a high-purity, thermosetting silicone with excellent stability and resistance to extreme temperatures. The process requires special handling before the material is injected and vulcanized in the heated mold. LSR is commonly used for precision products such as seals, electric connectors, infant products, medical devices, and kitchenware.

Related Products: LIQUID SILICONE RUBBER (LSR)

liquid-injection-moulding

liquid-injection-moulding

liquid-injection-moulding

liquid-injection-moulding

liquid-injection-moulding

liquid-injection-moulding

liquid-injection-moulding

liquid-injection-moulding

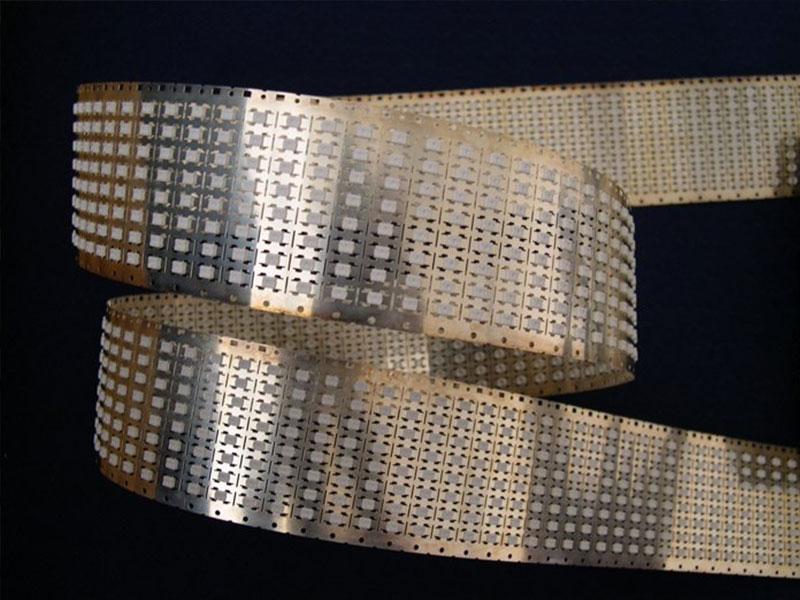

Powder Injection Moulding #

Powder injection molding (PIM) is a solution for manufacturing intricate metal or ceramic parts in medium to high volumes, typically ranging from 10,000 to over 2,000,000 parts annually. Using fine powders (less than 20 μm), PIM is suitable for parts weighing 0.1 to 250 grams, with cross-sections under 6.35 mm and tight tolerances (±0.3 to 0.5%). This process supports a wide range of materials, including various steels, alloys, and ceramics, enabling the production of high-precision, complex components.

Related Products: Contact Multiplas

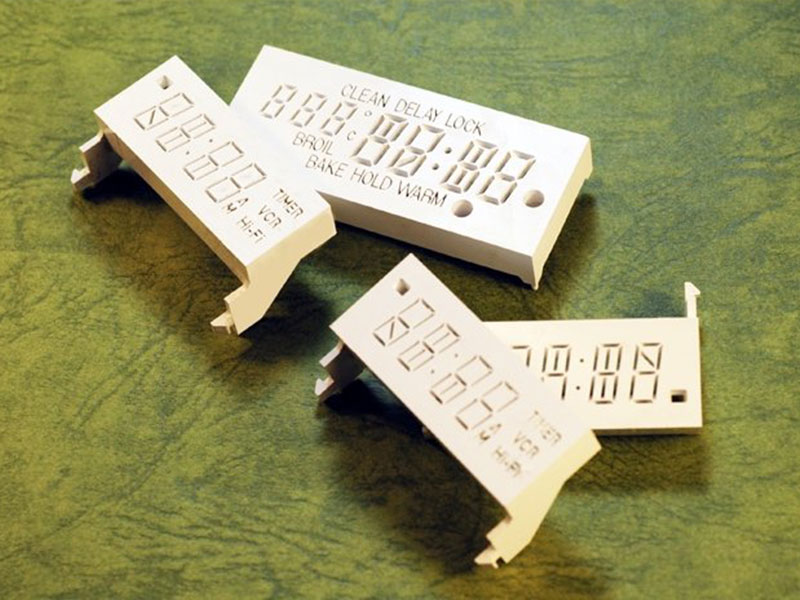

In-mold Decoration Molding #

In-mold Decoration (IMD) provides long-lasting decorative finishes with a variety of colors and textures. Unlike traditional surface printing methods, IMD places a printed film inside the mold, and molten plastic is injected behind it, bonding the film to the part. This technique can replicate effects such as metal, leather, wood, or stone. IMD technology includes In-mold Rolling (IMR), In-mold Labeling (IML, 2D), and In-mold Forming (IMF, 3D).

Related Products: Contact Multiplas

in-mold-decoration-molding

in-mold-decoration-molding

in-mold-decoration-molding

in-mold-decoration-molding

in-mold-decoration-molding

in-mold-decoration-molding

in-mold-decoration-molding

in-mold-decoration-molding

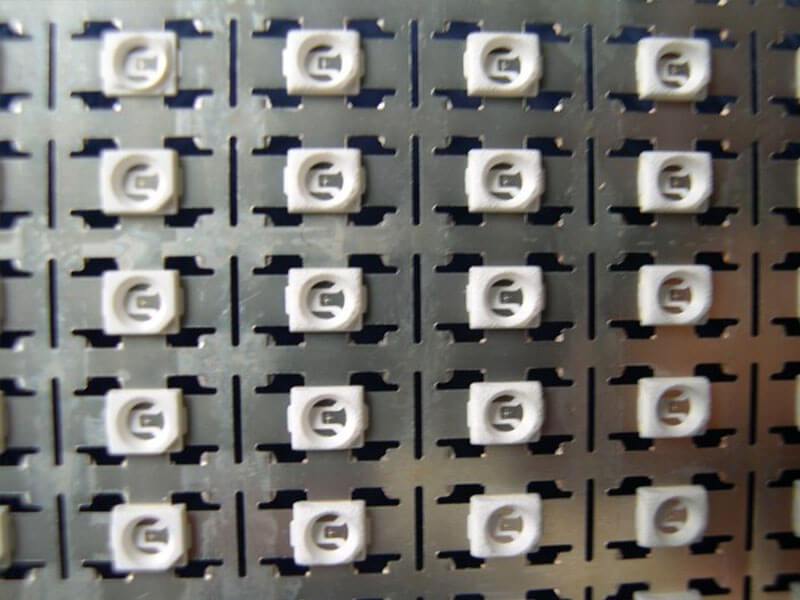

Micro Injection Moulding #

Micro injection molding is a specialized process for producing extremely small (less than 1 gram), highly accurate molded parts. Standard molding machines often struggle with such small components, but micro injection molding utilizes very high pressure and speed to achieve precise results. This technique is compatible with a wide range of materials, from high-temperature engineering plastics to commodity resins, and is ideal for applications requiring miniature, detailed parts.

insert-molding

insert-molding insert-molding

insert-molding insert-molding

insert-molding insert-molding

insert-molding insert-molding

insert-molding insert-molding

insert-molding thermoset-injection-molding

thermoset-injection-molding thermoset-injection-molding

thermoset-injection-molding powder-injection-moulding

powder-injection-moulding micro-injection-moulding

micro-injection-moulding micro-injection-moulding

micro-injection-moulding micro-injection-moulding

micro-injection-moulding micro-injection-moulding

micro-injection-moulding micro-injection-moulding

micro-injection-moulding micro-injection-moulding

micro-injection-moulding